What are the advantages of using Galvalume steel coil (GL)?

Release time:

2022-08-20 00:00

Source:

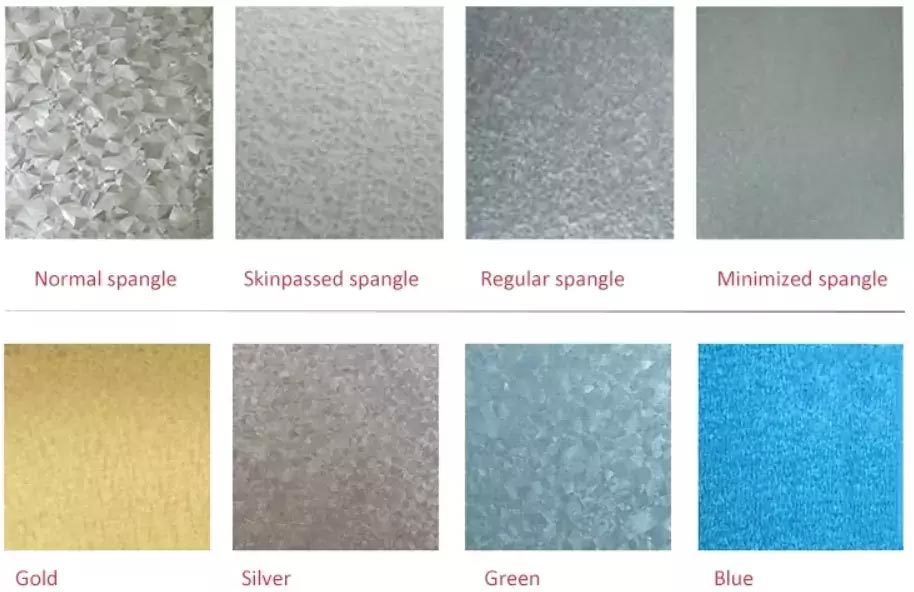

The surface of Galvalume steel coil (GL) has a characteristic smooth, flat and gorgeous star flower, and the base color is silvery white. The special coating structure makes it have excellent corrosion resistance. Long service life, good heat resistance, good adhesion between coating and paint film, good processing performance, can be punched, sheared, welded, etc., with good surface conductivity.

Good corrosion resistance, Galvalume steel coil (GL) has strong corrosion resistance, its corrosion resistance comes from the barrier protection function of aluminum and the dedicated protection function of zinc. When zinc is protected from cutting edges, scratches and coating scratches, aluminum forms an insoluble oxide layer that performs barrier protection. It also has a high thermal reflectivity, suitable as a roof material, and has excellent heat resistance, so it can be used in high temperature environments.

Recoatability, Galvalume steel coil (GL) can maintain excellent adhesion to the paint film, and can be directly painted or powdered without special pretreatment. Corrosion resistance after coating, after local coating and baking, the corrosion resistance of some parts without spraying decreases very little. Machinability, with excellent processing function, capable of punching, shearing, welding, etc., the coating has good adhesion and impact resistance. Electrical conductivity, the appearance can meet the needs of electromagnetic shielding through special waxing treatment.